OUR METHOD

Gain & Co Methodology

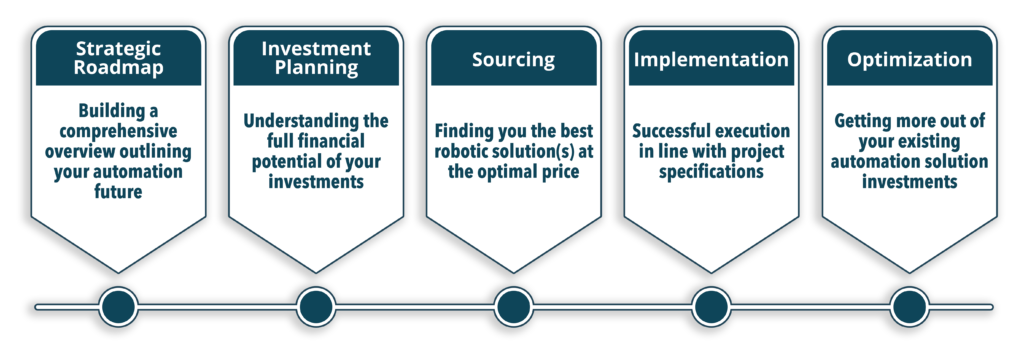

Our proven methodology can adapt to the scope of your needs, bringing results to your business through comprehensive planning, potential assessment, sourcing, implementation, all the way through to optimization.

We are happy to guide you through the entire journey, or support you on an individual phase basis.

STRATEGIC ROADMAP

Building a comprehensive overview outlining your automation future

- Automation Plan

- A comprehensive report outlining what is required to implement your automation strategy and achieve your operational objectives.

- Resource Plan

- A plan identifying the skills and resource gaps within your current organization necessary to address in order to ensure the successful execution of your automation plan.

- Exploring Opportunities

- Identifying and prioritizing opportunities for automation within your operational processes.

- Assessing Risks

- Pinpointing potential risks for automation failure and outlining mitigating actions.

- On-Site Observations

- We will observe your processes directly on the shop floor and collect relevant data to identify automation opportunities.

- On-Site Dialogue

- We will speak with key people from management to shop floor in order to fully understand your processes.

- Workshops

- We will conduct a kick-off workshop to get everyone aligned on the success criteria, as well as a prioritization workshop when risks and opportunities are identified.

INVESTMENT PLANNING

Understanding the full financial potential of your investments

- Investment & Scaling Plan

- A plan providing a global overview of how your investment opportunities can be rolled out across your business, including total expected return on investment.

- Potential Calculation

- An overview of the financial benefits expected to be achieved when specific processes are automated, focusing on:

- Increasing Productivity

- Improving Quality & Consistency

- Improving Safety Within Your Work Environment

- An overview of the financial benefits expected to be achieved when specific processes are automated, focusing on:

- Supplier Overview

- A worldwide market survey identifying qualified suppliers that have successfully completed similar projects before. The survey also provides a benchmark for the expected purchase price, enabling completing of the business case.

- Operator Training Plan

- A plan identifying training needs within your organization, ensuring that operators possess the necessary skills for the full utilization and proper maintenance of your automation solution(s).

- On-Site Observations

- Observing the specific processes directly on the shop floor and collecting relevant data to calculate automation benefits.

- On-Site Dialogue

- Engaging directly with your employees to understand the process to be automated and possible operator training needs.

- Market Research

- Our experts search the market and prepare a list of capable suppliers that fulfill your process needs. We then collaborate with you to narrow down a short list of the most capable suppliers which are chosen for further evaluation.

SOURCING

Finding you the best robotic solution(s) at the optimal price

- Requirement Specifications

- A detailed requirement specification allowing suppliers to clearly understand the technical and commercial requirements of your projects. This specification focuses on service, maintenance, etc. during the contract period.

- Industry Sourcing Assistance

- Advising your organization in the identification, evaluation, and negotiation of the supplier proposals you receive, enhancing the supplier’s performance, compliance, risk, and contract utilization.

- Competition Framework

- A complete competition framework clearly stating the terms and conditions for the tender agreement, informing the selection of the best suppliers based on both price and quality

- Contractor Alignment

- Aligning the proposal and competition framework with the delivery, ensuring both supplier and customer have a clear understanding of the contract in order to enable the best possible foundation for delivery.

- Sourcing Strategy

- Based on our collected insight, we gather a detailed overview focusing on marketing potential, supplier potential, cost-drivers, and acceptance criteria in adherence to operational strategy & budgeting.

- Sourcing Methodology

- Based on our proven sourcing method, we prepare a framework in which we create a competition between suppliers on price, quality, service, and solution performance.

- Contract Management

- Gain & Co can help identify the right stepping stones for further enhancing your automation benefits into the future. Automation next steps will provide you with the process innovation and technical inspiration for how the future of your operations can be designed.

IMPLEMENTATION

Successful execution in line with your project specifications

- Solution Verification

- We will help verify your selected automation solution design provided by the supplier, ensuring that you receive exactly what has been agreed upon.

- Implementation Support

- We will plan, drive, and verify that the supplier delivers Factory, Site, and Final Operational Acceptance Testing according to the agreement.

- Training & Communication Support

- We will support the implementation of your automation solution, providing communication plans and material to your organization to ensure successful automation.

- Project Management

- We will establish a regular meeting cadence between all parties to ensure transparency & timeliness. Status reports will be provided weekly, while a 2 month rolling plan is updated bi-weekly.

- Process Observations

- We will observe and analyze your operational processes directly on the shop floor, identifying areas to adjust for effective automation implementation.

- Interviews

- We will conduct brief interviews with key stakeholders, from management to shop floor, to address any remaining training needs or changes to governance processes.

OPTIMIZATION

Getting more out of your existing automation solution investments

- Optimization Plan

- Providing an overview of the current capacity of automation systems already implemented, and benchmarking these towards your expectations. This provides an additional plan for how to enable even better utilization and quick wins through optimization.

- Optimization Specification

- A complete specification allowing you to get quotations for the optimization tasks that much be completed to obtain additional benefits from your current solution.

- Resolution Plan & Specification

- A standalone offering for existing automation solutions you have invested in which are not living up to your expectations. We identify and describe any issues affecting performance, and compile a list of requirements that much be implemented to resolve these issues, providing a path forward to an effective resolution.

- On-Site Process Observations

- We will observe your operations processes directly on the shop floor to identify bottlenecks and inefficiencies affecting the overall performance.

- Technical Inspection

- We will analyze the technical abilities of the automation solution to identify root causes for poor performance.